Rotary Indexing Machines

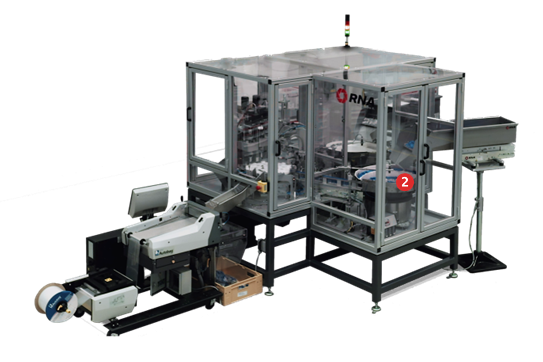

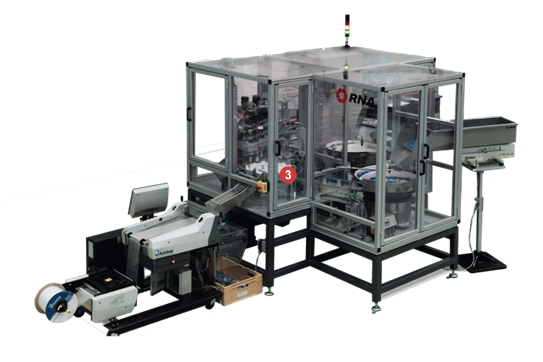

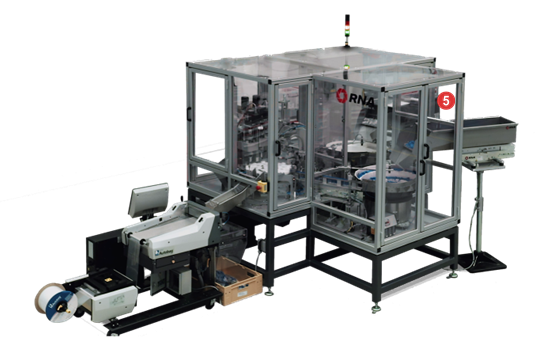

The rotary indexing system is a sophisticated and highly efficient mechanism used in various industries to streamline production processes. RNA design and develop rotary indexing machines that are tailored to the customer’s specific applications.

Downloads

FEATURES

- High precision and repeatability- Floor-space saving

- Semi/fully automated systems

- Tailored to the customer’s specific applications

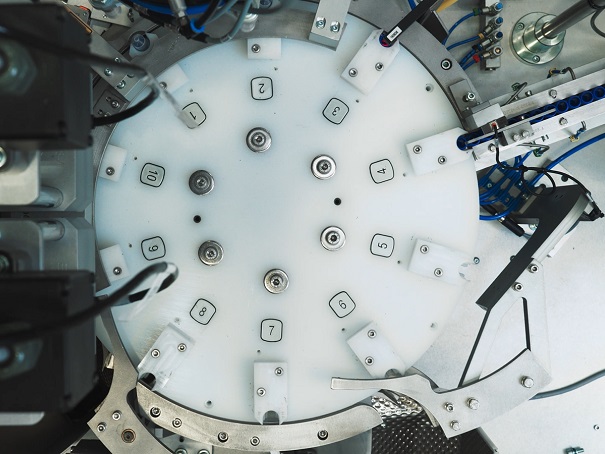

Having extensive experience in rotary assembly and testing machinery, RNA have designed and developed a broad range of solutions from simple two-station rotary machines up to highly complex 10-station rotary machines.

RNA rotary indexing machines are especially well-suited for assembly machines that requires a compact installation space. We carefully evaluate the context of your operations, depending on applications, combine rotary indexing tables with our custom machines to suit our customers’ diverse needs.

RNA Rotary Indexing Machines

- Tailored to the customer’s specific applications

- Reliable, high quality

- High precision and repeatability

- High productivity

- Cost effective

- Low maintenance

- Floor-space saving

- Easy to upgrade to suit various parts

- Semi or fully automated systems

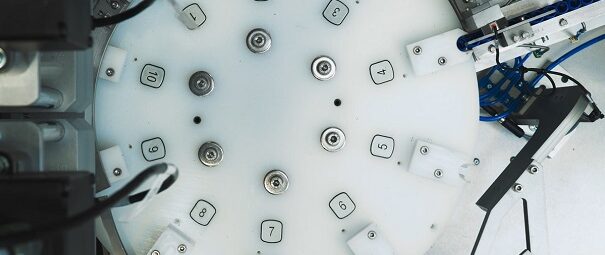

Key Components of a Rotary Indexing Machine

Enhanced Precision

The rotary indexing system offers exceptional accuracy, reducing errors and improving the quality of the assembled products.Increased Productivity

By eliminating manual handling and optimizing production flow, the rotary indexing system enhances overall productivity and output.Flexibility

The system can be easily adapted to accommodate different product sizes and assembly tasks, providing versatility in manufacturing operations.Cost Efficiency

With reduced labour requirements and improved production rates, the rotary indexing system contributes to cost savings over time.Space Optimization

The compact design of the rotary indexing system optimizes floor space, making it suitable for assembly workstations with limited areas.What is a Rotary Indexing System?

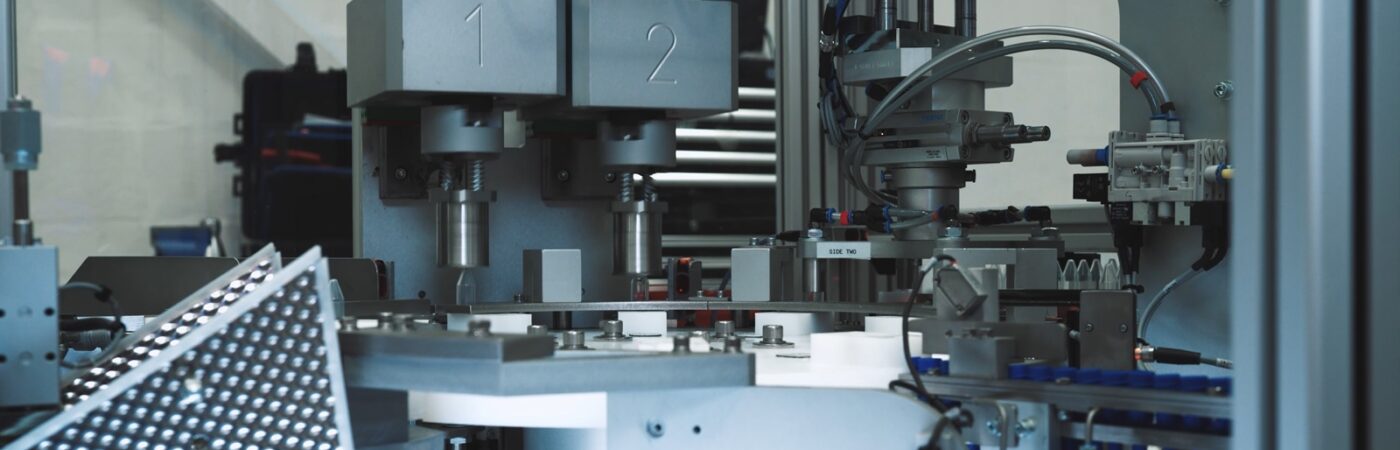

The rotary indexing system is a sophisticated and highly efficient mechanism used in various industries to streamline production processes. This automation technology enables the precise movement and positioning of workpieces at predetermined intervals, allowing assembly workstations to perform specific tasks with exceptional accuracy.

How does a rotary indexing system work?

The rotary indexing system is a type of automation technology that facilitates the rotational movement of workpieces within a manufacturing or assembly line. It operates on the principle of indexing, which involves moving the workpiece from one station to the next in fixed angular increments or positions. The rotary motion can be continuous or step-by-step, depending on the specific production requirements.

Rotary Indexing Machines Applications

- Assembly

- Machining

- Testing

- Printing

- Positioning and transfer

- Parts separation

Applications

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.