What’s the difference between an industrial robot and a cobot?

So what are the main differences between robots and cobots? Understanding how both robots and cobots interact with humans is the key to comprehending why they are fundamentally different.

We’ll slide into the main reasons they perform and function differently as well as the industries that most commonly use them.

What is a cobot?

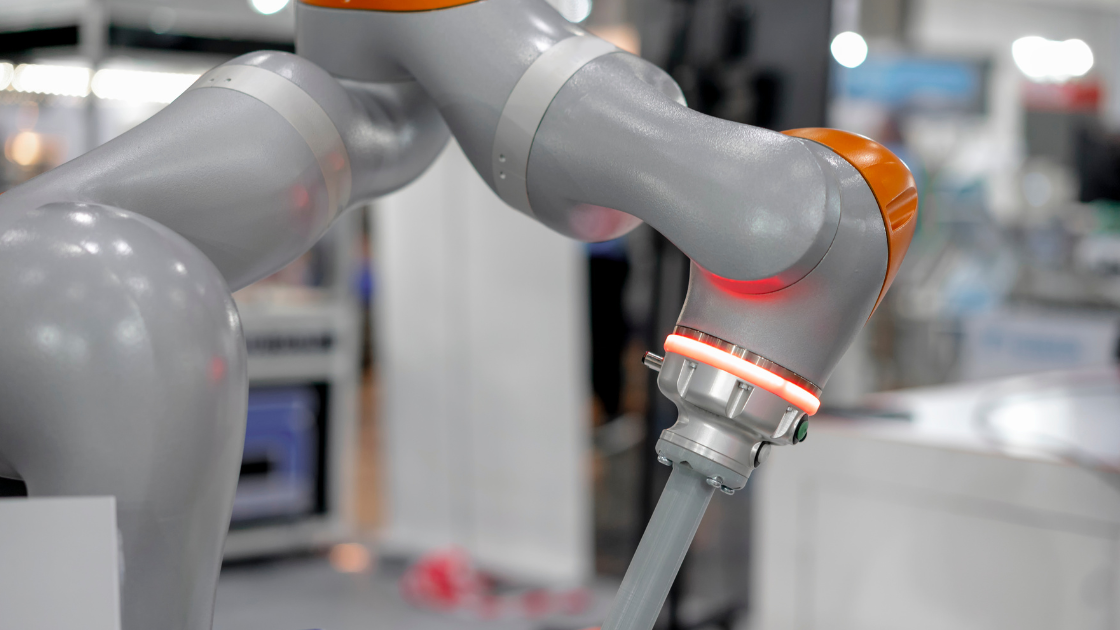

Also known as collaborative robots, cobots operate in tandem with humans to complete an array of tasks in different industries. There are different categories of cobots whose functionality varies depending on the task at hand.

Cobots are often found completing multiple low skill level tasks which leave humans to focus on more sophisticated problem solving tasks. There are four types of collaborative robots:

Power and force limiting cobots

Human and cobot work together without any safety barriers.

Safety rated and monitored stop cobots

A cobot is activated once the human has left the operating space for safety reasons.

Speed and separation cobots

These ‘fenceless’ cobots allow humans and cobot to work in the same space at the same time with a predetermined distance set out before the task begins.

Hand guided cobots

Humans hand guide the cobot. The cobot responds to the operator’s direct input to perform tasks.

What is a robot?

Traditional robots are commonly found working in total replacement of humans. Unlike the cobot, the robot will complete single tasks at speed. Robots are programmed to complete the task with no human interaction.

It’s been acknowledged that traditional robots have not been designed with human’s safety at the core of their creation. There are six main types of industrial robots:

Cartisan

Has three axes of control that are all at right angles to each other.

Scara

Stands for Selective Compliance Assembly Robot Arm and operates in the same fashion as an arm would.

Cylindrical

Has a rotating shaft which slides in a vertical motion.

Delta

Consists of three arms that are all connected to a base.

Polar

Have a combined linear joint and two rotary joints with an arm connected to a base.

Vertically articulated

Commonly used for assembling, welding and material handling.

The key differences between a robot and a cobot

Working with humans

The cobots will always have some form of interaction with humans. Whether it be fenceless or hand guided by the human, the cobots are set to complete multiple tasks with ease.

Safety

The consideration of human safety in cobots is paramount. Robots, due to their non duality with humans, are considered to be more dangerous if a human is entering the operating space.

Functionality and Ease

Cobots vary in size, but are far more easily transportable and can be placed on walls, ceilings and into different areas with little complications.

Furthermore, the ability to program and update cobots is considerably easier as they adapt to new skills. Robots are standardly only capable of performing one key operation.

Maintenance on these larger industrial robots can be more problematic with major setbacks to production.

What’s right for you?

You might have multiple questions about whether a robot or cobot is best suited to your project or industry. If you’d like to discover more about cobots, read our blog post or get in touch with our highly experienced team to find the best automation solution for you.