Digital Bowl Feeders

RNA’s digital Bowl Feeders are the feeding technology of tomorrow and unique in the world. With the help of AI and 3D Geometric Deep Learning, we are able to generate a digital twin of the feeding system and simulate it before building the system.

RNA OFFER

Digital Bowl FeedersDigital Bowl Feeders (3D Printed)

Before production starts, the sorting solutions we design can be tested, checked and approved by the simulation. Even before the concept is drawn up, we can see whether a component part can be fed and you can be sure that the solution will work. Many of our bowl feeders are already digitised and can be offered for your application.

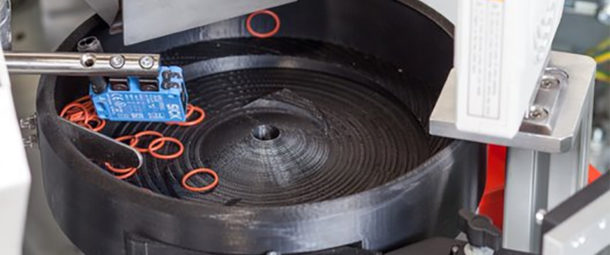

The RNA digital bowl feeder is equipped with a sorting track (material-specific tooling), which can be milled or 3D printed. The custom tooling can be produced following simulation and assessment of the bulk material. The optimal geometry of each individual tooling is calculated through a multiphysics simulation and with the help of 3D Deep Learning AI technology. This guarantees congruence between the technical simulation of the feeding process and the actual behaviour of the assembly parts in practice. The transfer of the bulk material to the linear line is thus completely trouble-free. The new digital possibilities of RNA are also used in conventional feeding technology.

Full Reproducibility

CNC-milled or 3D-printed for full reproducibilityAI Optimisation

AI (Artificial Intelligence) for maximum efficiency3D Deep Learning

3D (Geometric) Deep Learning for the development of sorting linesDigital Pre-Testing

Digital pre-testing through simulation of the feeding systemDigital Twin Accuracy

Digital twin for 100% reproducibilityMaterial Flexibility

Flexible changeover to a new materialPart Family Feeding

Feeding of different parts of a part familyHigh-Performance

Superior Feeding System CapabilitiesDigital Bowl Feeders with 3D Printed Bowls

RNA 3D printed bowl feeders are designed and produced using 3D printing technology, allowing for rapid customisation and completely reproducible. They are flexible and can be quickly changed over for different part shapes and sizes, which makes them ideal for industries requiring high flexibility such as electronics or small parts manufacturing.

- Simulation in Advance of Production: Designs can be simulated and tested virtually before production, ensuring optimal performance and reducing the need for physical prototypes.

- Reproducible & Consistent: The digital nature of 3D printing ensures that bowl feeders can be easily reproduced with consistent quality across multiple units.

- Customisation & Flexibility: Easily customised for various part shapes, sizes, and orientations.

- Cost-Effective: Lower production costs due to reduced material waste and the ability to produce complex designs without additional tooling.

- Compact Design: 3D printed feeders are typically lighter than metal counterparts, allowing for easier handling and installation.

- Design Complexity: Ability to create intricate designs, channels, and features that would be challenging with conventional manufacturing.

- Short Lead Times: Faster production cycle enables quick response to design changes or manufacturing demands.

Applications

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.