Challenge

- Provide a flexible automation solution for various different components (11 variants)

- Provide quick and easy changeover between component runs

- Provide 100% inspection on position, entry hole size and exit hole size

Solution

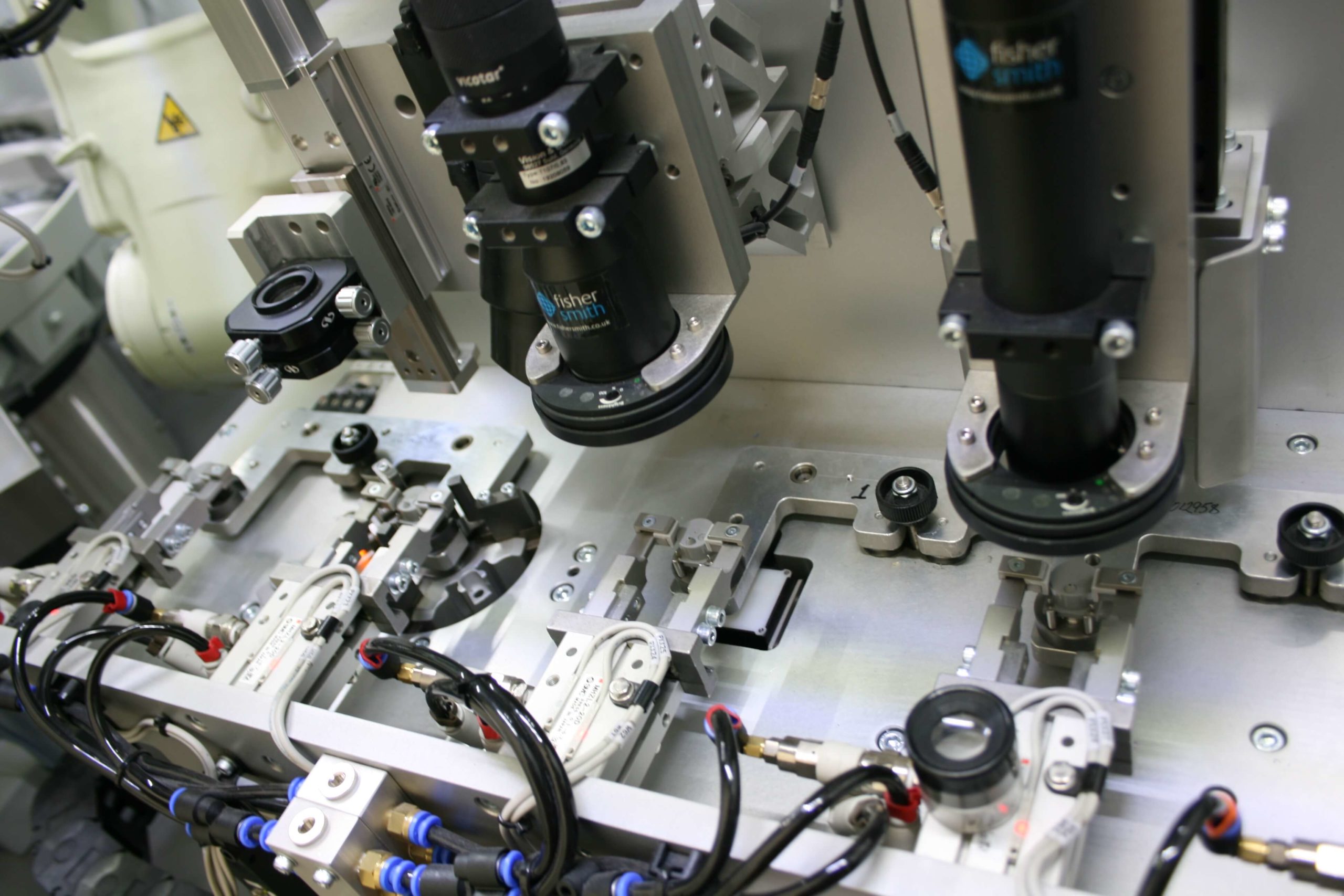

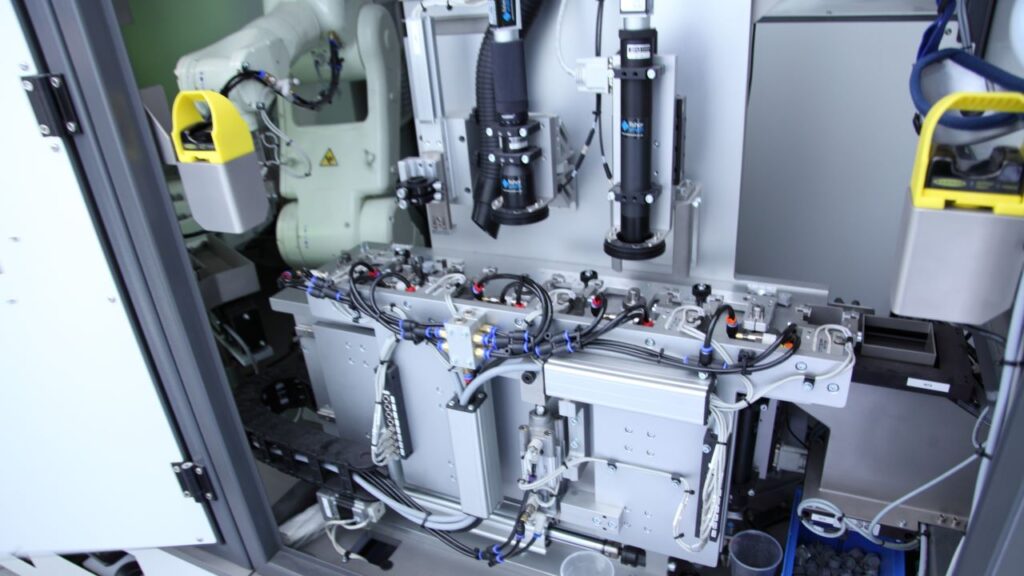

The figure shows the main functional elements of the solution. This particular configuration utilizes one laser drilling station and three camera stations to verify part accuracy.

To begin the process, the components are presented to a vision guided robot by an RNA bowl feeder that feeds parts onto a pick conveyor mounted below the robot. The robot then picks the component and places it in the correct orientation to a nest mounted on a walking beam transfer system.

With the walking beam transfer system, the component is lifted up by a gripper and moved one position ahead to the laser station. The laser drilling process is triggered and drills the correct size hole in the desired position.

The laser drilling system is supplied by ES Technology who have extensive experience in laser drilling, welding & marking systems, delivering a quality performance at high speed and with great precision. After the component is drilled, the component is lifted up again and moved to the next station for the first inspection.

RNA enlisted the expertise of our machine vision partner Fisher Smith, who are leading experts in the field of machine vision and industrial control systems. The vision system incorporates 3 camera stations, with the ability to inspect each component for position of the hole, entry hole size and exit hole size. Components that fail the vision inspection are rejected into a reject bin. ‘Good’ components are fed into a collection bin for the bagging system and a separate bin for random sampling (1/1000 of ‘good’ components for further off-line checking).

This system has the flexibility to handle various components (11 variants). The bowl feed system utilises an innovative quick-change tooling system that speeds up tooling changes. First, each component variant is provided with a unique barcode which contains all the parameters set up for that particular component. When the barcode is scanned, the data is retrieved by the control PC and then the operator should change the tooling models to meet all those parameters. The control PC automatically recognizes if incorrect sets of tooling are fitted. This validation process takes just seconds, and eliminates the risk of inadvertent human errors.

A fully validated changeover to switch from one component to another can be accomplished in less than 5 minutes, resulting in improved uptime and productivity.