Solution

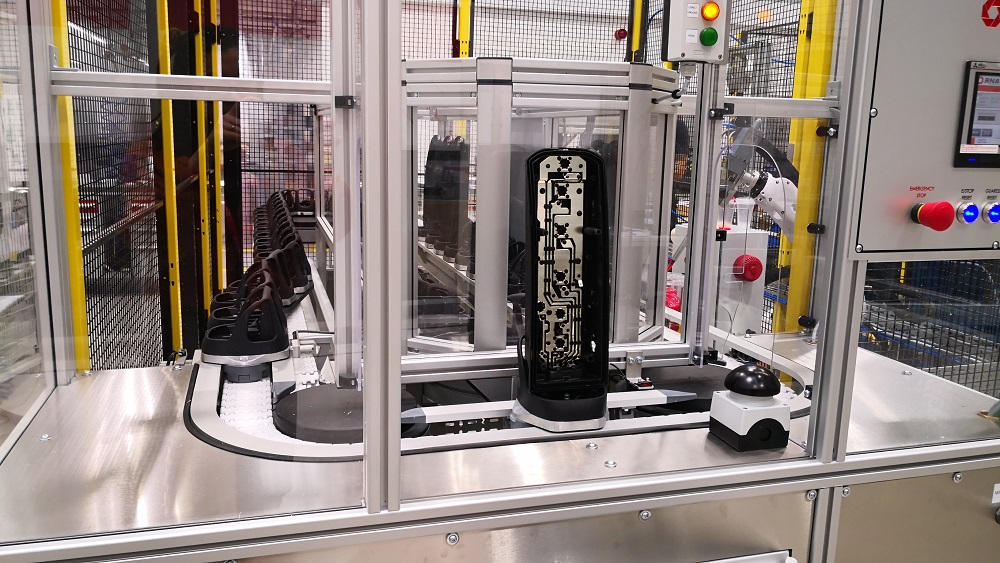

The machine consists of a 6-axis dispensing robot, a vision inspection station and a temperature-controlled chamber, based on a conveyor system holding 50 component nesting pallets.

The operator loads the housing into the component nesting as part of the conveyor pallet system. The pallet makes its way to the robot dispensing system where the resin pot is applied. The pallet with housing is then inspected by the vision system for a complete pot shot present. On passing the vision inspection the pallet travels through a temperature-controlled chamber applying local heat to the housing to cure the resin. The pallet is then conveyed to the operator station at a controlled temperature which can be manually handled. The housing is removed from the pallet by the operator and passed on to the next process.

A 6-axis robot is integrated with a resin dispensing system and automating this process step has created a more uniform high quality of the dispensing and has also freed up employees to attend to other tasks.

The vision inspection station integrates a camera to perform quality inspections. The housings are stopped at the station and the vision checks resin material has been dispensed. This ensures that the dispensing results are accurate before moving on to the next step.

At the horseshoe-shaped conveyor system, the pallet with housing moves clockwise on the conveyor, travelling around the track at about 0.5m/min. This allows the resin material to settle, then apply some gentle radiated heat (50 degrees) locally inside the housing at the temperature-controlled chamber.

3D printing has been used to test component nesting designs. With in-house 3D printing, different design prototypes were created to check the fit of the interface between the housing and the nest.

All 50 pallets were 3D printed. They were highly successful in achieving complete reduction of assembly labour, delivered ahead of schedule as manufacturing the batch of 50 pallets only took 4 days, and it also gave the operator a product which was highly functional; far more so than would likely have been achieved by a conventional approach.

Key features & benefits

- Human-automation collaboration of the resin dispensing process

- Increase productivity and consistency and reduce rework

- Provide precision and repeatability

- Maintain high quality of manufactured components

- Floor-space saving

Other Case Studies

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.