Solution

The customer had a requirement for an automatic insertion cell to put brass inserts into the holes in the cover moulding and clip the three cover mouldings together.

The automation is designed to insert the brass inserts into the cover mouldings.

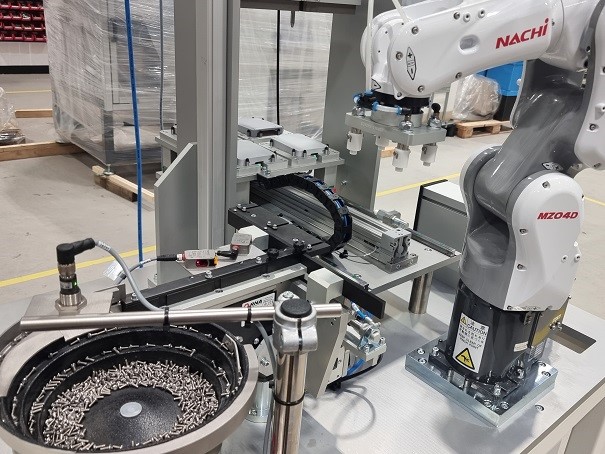

Brass Insert Feeder

A vibratory bowl feeder sorts and feeds the brass inserts. The bodies are fed in single file onto a vibratory linear with the head at the top for transporting to the 3-position escapement unit.

6 Axis Robot Stage 1

The robot picks the first two parts from the escapement with vacuum, then picks the other two once the escapement has re-shuttled across. The robot then places all four inserts into the two cover mouldings that has been placed on the carriage by the customer’s demould robot.

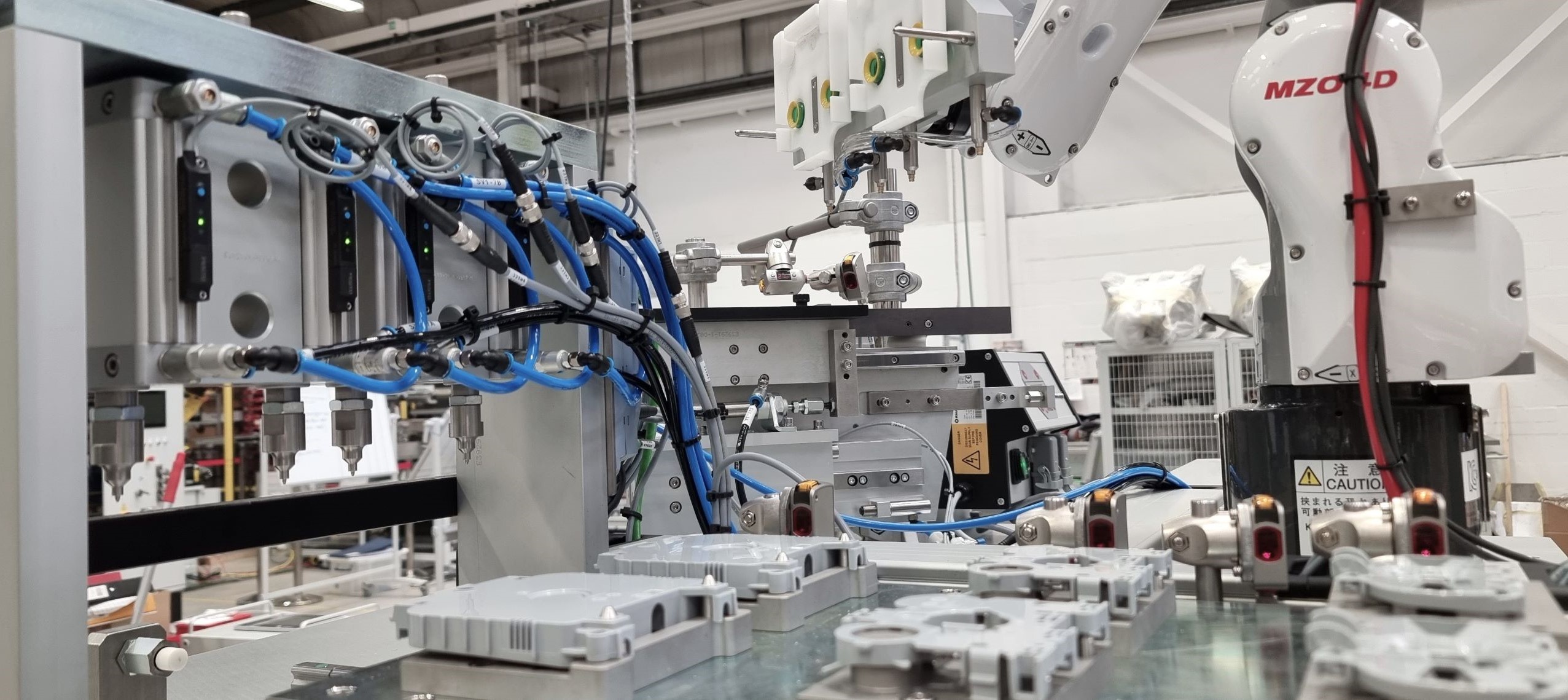

Carriage and Press Station

The carriage moves under the press position. The 4 independent heads come down and insert the brass inserts into the covers. The presses are retracted, and carriage returns to the robot pick and place position.

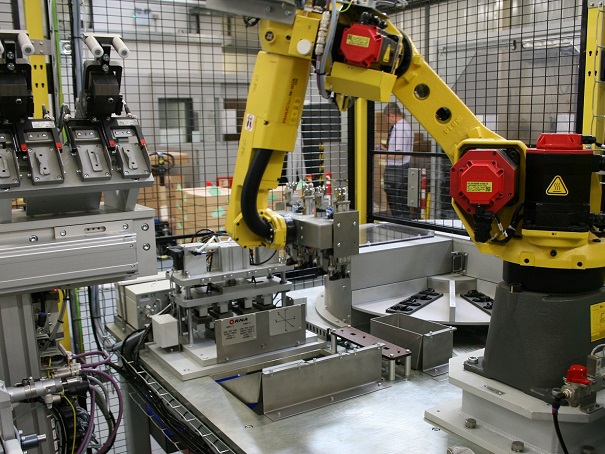

6 Axis Robot Stage 2

The robot picks both covers with vacuum and places them over the inner mouldings and clicks them into place.

Once this has been completed, the robot picks both parts up and places them over the hinge components and clicks them together.

The robot would then move the full assemblies to the outfeed.

Brass Insert Feeder

Brass Insert Feeder

6 Axis Robot picks and places brass inserts

6 Axis Robot picks and places brass inserts

Carriage and Press Station

Carriage and Press Station

6 Axis Robot assembles three sets of moulding parts

6 Axis Robot assembles three sets of moulding parts