Solution

Due to the nature of the products, it was impossible to mechanically check the orientation of the capsules. Therefore, a vision system was applied to meet the requirements of this application perfectly.

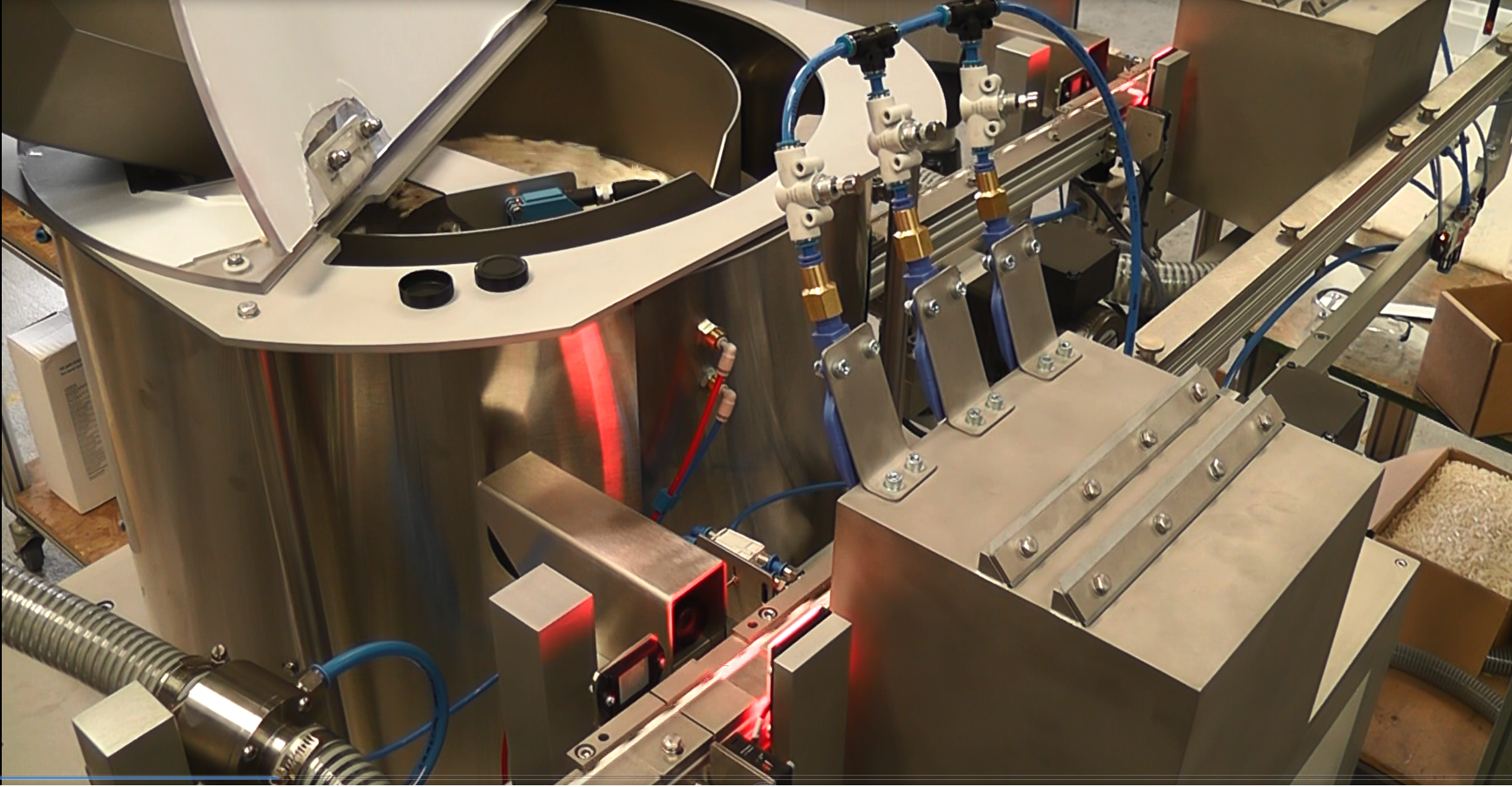

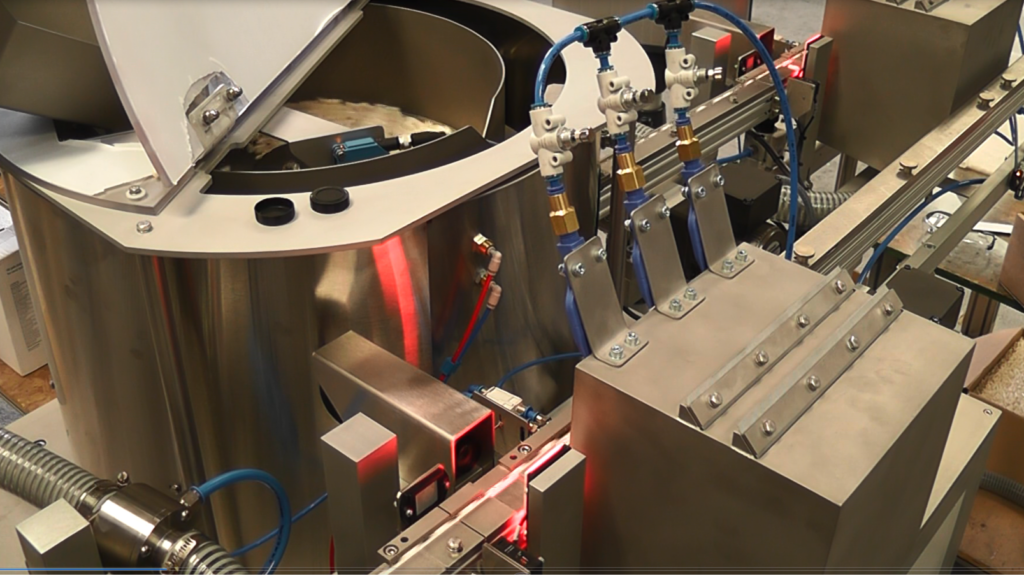

The filled capsules are stored and transferred by bulk feeder on demand to a centrifugal feeder, then discharged from the feeder to the conveyor out-feed. An orientation station (camera station) is fitted with the conveyor out-feed to check capsules orientation. Correctly orientated capsules will pass through the station and continue along the conveyor out-feed; Incorrectly orientated capsules will be detected and recycled back into the bulk feeder via a vacuum air system.

Key Features

- Bulk feeder

- Centrifugal feeder

- Conveyor out-feed

- Orientation Station

- Control system