Solution

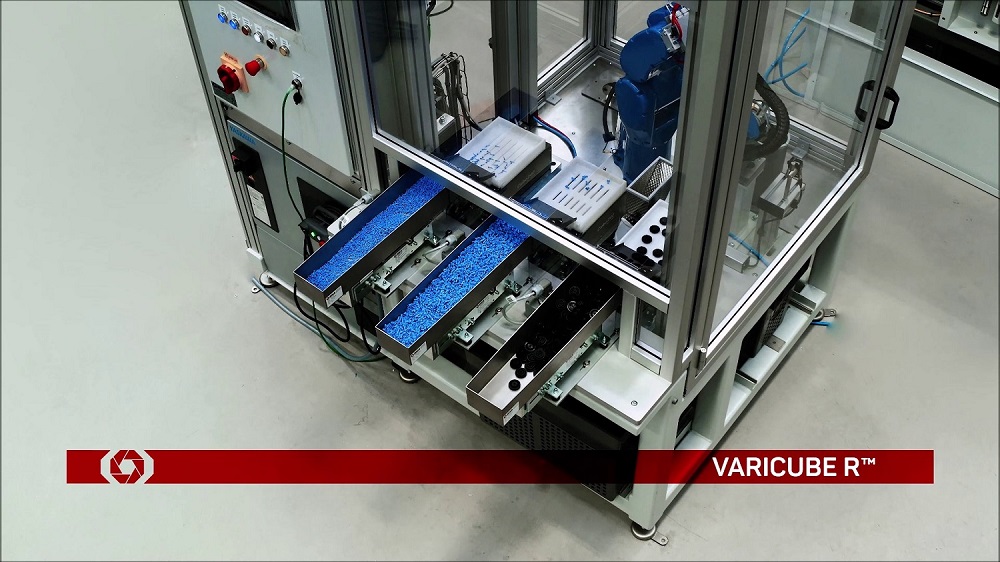

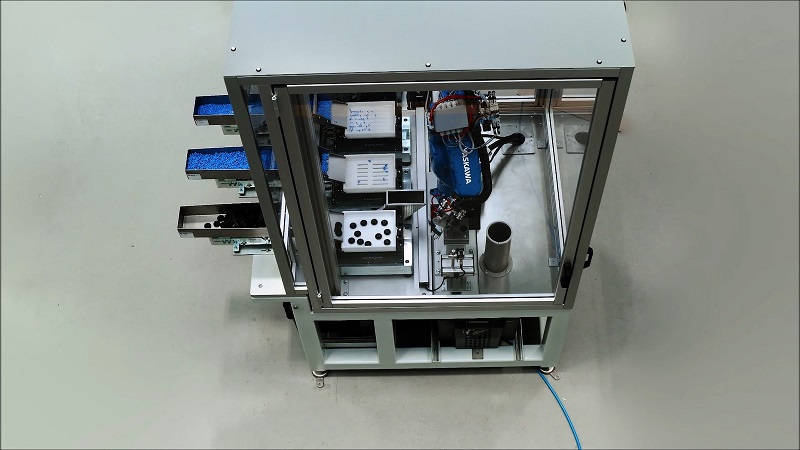

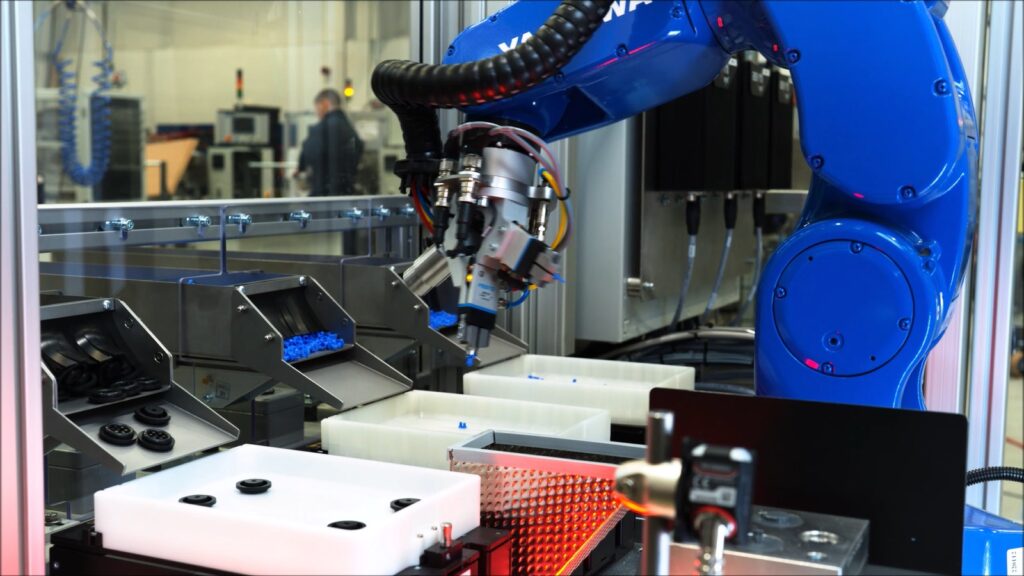

RNA’s VariCube R™ is a standard flexible assembly solution that utilises intelligent vibration platforms, coupled with industrial machine vision recognition and a 6-axis robot to feed and assemble component parts of various shapes and sizes.

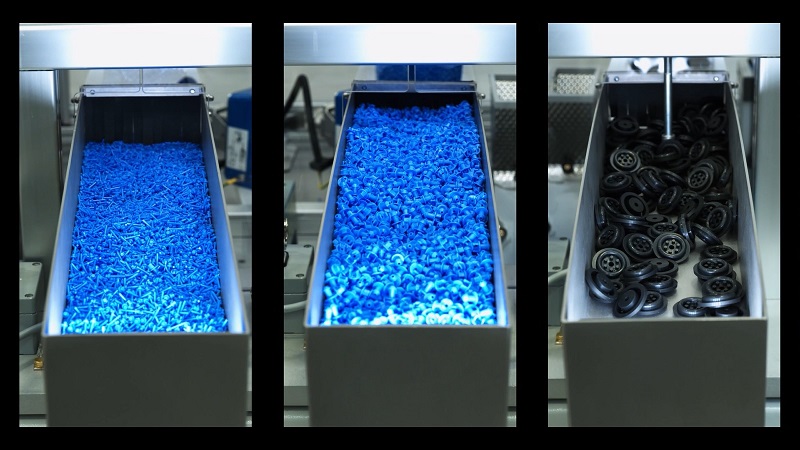

RNA FlexCube™ flexible vibration feeders

Various parts to be assembled are loaded in bulk into hoppers. Parts drop by vibration from hoppers onto FlexCube backlit vibratory platforms on demand. The FlexCube complete pre-programmed vibratory cycles to orientate and separate component parts, presenting them to an integrated EYE+ vision system for robot pick.

6-Axis Robot

The EYE+ vision system inspects the component parts on the FlexCube platforms and identifies which are laying in a position suitable for being picked. The coordinates are sent to the robot. A 6-Axis Robot, with suitable end of arm tolling picks all identified component parts and places them in the proper orientation into the assembly nest.

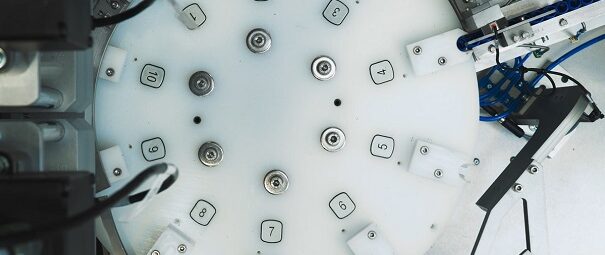

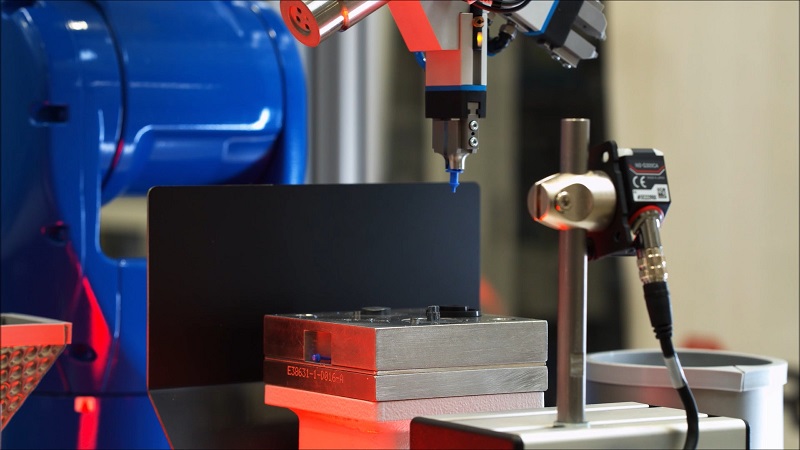

Assembly Fixture

The assembly fixture comprises of main diaphragm assembly and pin assembly locations. The fixture is located by dowels for interchangeability and incorporate part present sensing. An overhead mounted vision system confirms positioning of the component parts before final assembly. The robot then assembles the pin assembly to depth in the diaphragm central cavity.

Unload

The robot unloads assembled component parts to a storage box via an unload chute.

Hoppers

Hoppers FlexCube Vibration Feeders

FlexCube Vibration Feeders Assembly Robot

Assembly Robot Assembly Fixture

Assembly Fixture