In the rapidly evolving landscape of automation, technology continues to push the boundaries of what is possible. One such innovation that is transforming industries is 3D printed end of arm tooling. This cutting-edge development is streamlining manufacturing processes, enhancing precision, and driving efficiency to unprecedented levels.

In this blog, we go into how 3D printed end of arm tooling assists automation.

What is 3D Printed End of Arm Tooling?

End-of-arm tooling, commonly referred to as EOAT, is an essential element in robotics and automation systems. EOAT encompasses the various attachments or tools that robots use to perform specific tasks within automated systems, such as gripping, lifting, sorting, welding, and more. The custom designed EOAT is crucial because it directly impacts a robot’s ability to handle different objects and perform its assigned tasks effectively.

Traditionally, EOAT was manufactured using conventional methods, such as CNC machining and injection moulding. These techniques often involved time-consuming and costly processes that made customisation and rapid iterations challenging.

3D printed end of arm tooling refers to specialised robotic attachments or manipulators that are created using additive manufacturing techniques. The process involves depositing material layer by layer to construct complex geometries, allowing for highly tailored solutions to meet the unique demands of various industries.

Read more: Harnessing Developments in 3D Printing Technology for Manufacturing Innovation and find out how 3D printing helps RNA to drive innovative ideas through the business.

Benefits of 3D Printed End of Arm Tooling:

Customisation and Flexibility:

Traditional manufacturing methods often require costly and time-consuming processes to create customized tooling. 3D printing offers unparalleled flexibility, enabling the rapid prototyping and production of end of arm tooling tailored to specific applications. This adaptability empowers manufacturers to quickly respond to changing production needs.

● Lightweight Design:

3D printing allows for the creation of lightweight, complex structures that are otherwise difficult to achieve with traditional manufacturing methods. Lighter EOAT means less strain on robotic arms and, in turn, reduced maintenance and longer equipment lifespan.

● Complex Geometries and Intricate Features:

Additive manufacturing unlocks the potential to create intricate, complex shapes and features that would be impractical or impossible using traditional methods. This capability is invaluable for tasks requiring precise manipulation or interaction with intricate component parts.

● Reduced Production Costs:

Traditional machining or casting processes often involve significant material wastage. 3D printing, on the other hand, is an additive process that minimises material usage. Moreover, it eliminates the need for expensive tooling and moulds, resulting in substantial cost savings.

● Speed of Prototyping and Production:

The speed at which end of arm tooling can be prototyped and manufactured using 3D printing is a

game-changer. Rapid iteration and testing allow for quicker development cycles, ultimately expediting the deployment of automated systems.

● Improved Performance and Productivity:

The precision and accuracy achievable with 3D printed end of arm tooling significantly enhance the

performance of robotic systems, resulting in higher productivity, reduced cycle times, and improved overall efficiency in manufacturing processes.

● Reduced Downtime and Maintenance Costs:

3D printed end of arm tooling is inherently durable and can be designed to withstand harsh operating environments. This durability leads to longer tool lifespans, reducing the frequency of replacements and associated downtime and maintenance costs.

Read more:

- Harnessing Developments in 3D Printing Technology for Manufacturing Innovation

- How to Choose – Options for Part Presentation in Robotic Assembly

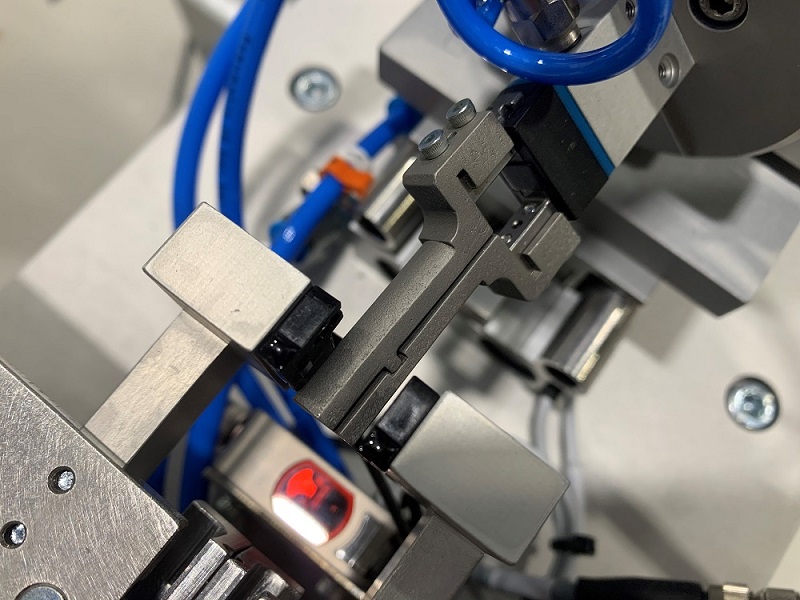

Miniature gripper jaws printed in 316 stainless following prototype development and testing. Image by RNA

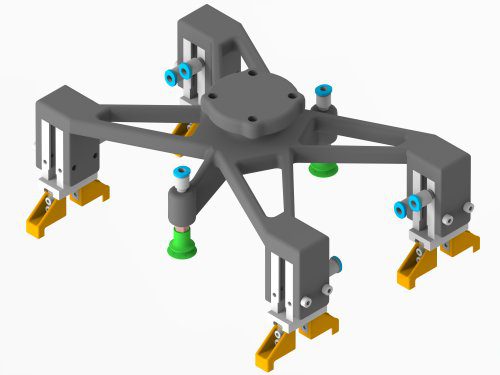

Iterative concept development for component nesting; initial concept (left) to finish product (right). Image by RNA

3D printed tools are well-suited for COBOT applications. Image by Fox Precision Tooling

Real-World Applications:

The applications of 3D printed end-of-arm tooling are vast and diverse. Industries such as automotive automation systems, electronics assembly, food processing, and e-commerce distribution centres have already embraced this technology. The ability to create customised end-of-arm tooling for specific tasks has led to increased automation in these industries, resulting in higher production rates and improved quality control.

Conclusion

The adoption of 3D printed end of arm tooling represents a paradigm shift in the automation industry. With its unparalleled customisation, reduced production costs, and enhanced performance capabilities, this technology is driving efficiency and precision to new heights. As industries continue to embrace automation, 3D printed end of arm tooling will undoubtedly play a pivotal role in shaping the future of manufacturing.

Want to learn more about the 3D end of arm tooling and automated manufacturing solutions we offer? Get in contact with RNA today by calling us on +44 (0)121 749 2566 or sending an email to [email protected].