Vibratory bowl feeders are indispensable tools in many manufacturing processes. They efficiently sort, orientate, and feed components, making them crucial for industries ranging from automotive to electronics. However, like any machinery, they require regular service and maintenance to ensure they continue to operate at peak efficiency.

Routine Maintenance

To maximise uptime and performance, vibratory bowl feeders should be maintained on a regular basis. Daily, weekly and monthly inspections and cleaning should be performed by operators, while more complex preventative maintenance should be conducted by our qualified technicians on an annual basis.

Annual Service

Vibratory bowl feed systems should be scheduled for annual preventative maintenance by our experienced service technicians. This can involve disassembling major components and thoroughly inspecting, cleaning, and replacing worn parts.

A detailed inspection beginning by examining the feeder for any visible signs of wear, damage, or loose components. Looking for cracks, deformities, or excessive wear on the bowl surface. Inspection of the springs, bolts, and other fasteners for signs of fatigue or degradation. This visual assessment provides an initial overview of the feeder’s condition.

Specific tasks thereafter include:

- Disassemble and thoroughly clean all necessary components.

- Repair or replace any well-worn or damaged elements that can be replaced on site.

- Upgrade any outdated or failing components.

- Perform calibrations and test runs to confirm meets OEM specs.

Read more:

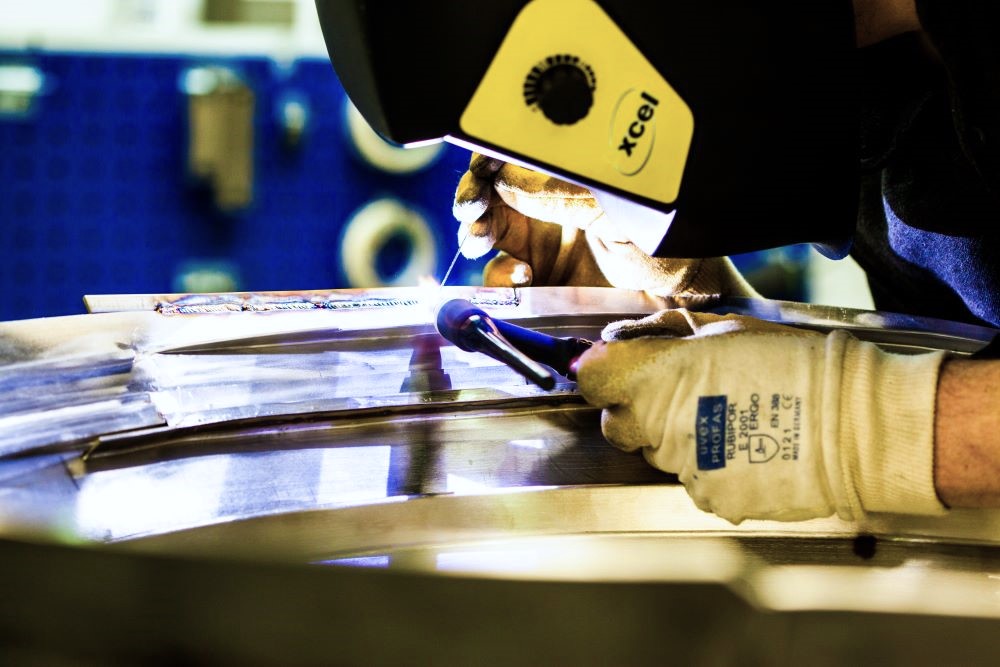

Servicing and preventative maintenance can save significant lost production time over the life of your equipment. Image by RNA

This comprehensive annual service ensures the feeder bowl operates at peak efficiency and prevents premature breakdowns. Technicians will also make recommendations for upgrades, repairs, and design improvements if needed such as:

- Replace bowl liners and cradles when worn to ensure proper part trajectories.

- Reline and resurface the bowl.

- Refurbish or replace old drive coils and mechanisms to maintain efficiency.

- Replace or repair worn or damaged tooling.

Conclusion

By performing annual service procedures, you can maximise uptime on these critical automation systems. The costs of preventative maintenance are far outweighed by the expense and production impacts of unplanned downtime on the factory floor.

Want to learn more about RNA Services? Get in contact with RNA’s Service and Spares Team today by calling us on +44 (0)121 749 2566 or sending an email to [email protected].