Knowledge-based engineering (KBE) is an engineering methodology used to capture engineering information systematically into design systems. This supports the re-use of case study data and application of previously acquired knowledge in the improvement of engineering activities. The philosophy brings an array of benefits, both tangible and intangible, including reducing costs and lead time for new product development, as well as centralising technical data in a way which can be shared by a wider team, regardless of the individuals own experience level.

As the world’s leading supplier of feeding and handling systems, the development of RNA’s bespoke feeding and automated handling solutions are highly knowledge and experience driven. The most valuable engineering knowledge including parts handling knowledge and the knowledge of the process of designing the feeding system lies within the heads of RNA’s experienced engineers, who are scattered across our seven manufacturing divisions in Europe.

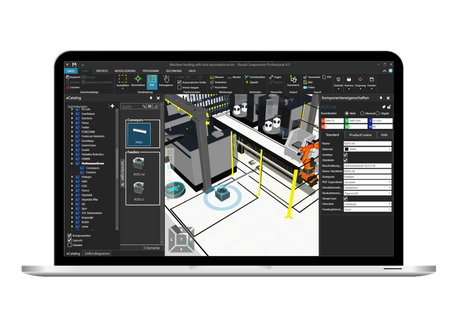

Applying Knowledge-Based Engineering approach RNA have developed a KBE system wherein the knowledge of the feeding system and its design process is captured. The KBS system holds the application specific technical data enables this information to support our engineering teams in the design and development of new feeding systems, based on proven concepts of a similar nature.

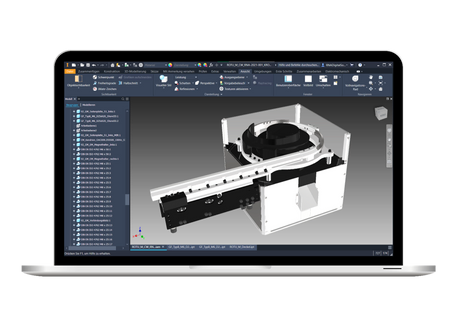

The RNA KBE system constitutes the integration of artificial intelligence (AI), and computer-aided design (CAD). The system covers empirical knowledge from 50,000 feeding projects in AI, collecting information from all subsidiaries companies of the Rhein-Nadel Group. The CAD provides ‘design automation’ capabilities, allowing component parts, assemblies, and drawings to be parametrically varied.

The RNA KBE system ensures that the knowledge of every feeding project is captured and continuously enhanced and reused for new projects. Most importantly, it offers our customers reduced system cost, compressed system development times and a significant reduction in project risk.

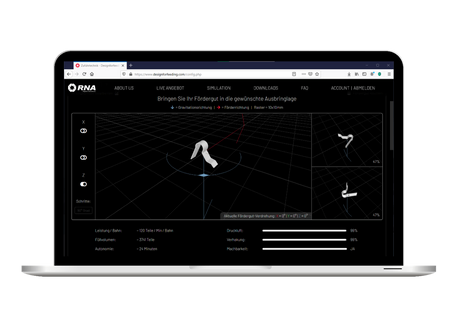

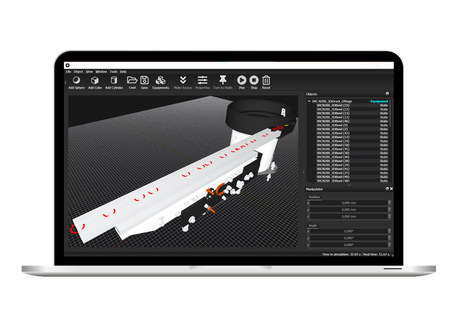

In addition, RNA’s KBE system with AI and Multiphysics simulation has the ability to develop the concept for feeding systems completely digitally, by pre-simulating the feeding process and orienting tooling features, which helps in rapid feasibility assessment to meet customer specifications. The system provides early proof of concept and enhances customer confidence and experience.

RNA KBE System

Feasibility, delivery time, costs & more

CAD design

Fully reproducible

Digital twin

Development without real parts

Shaping layout

Early stage planning