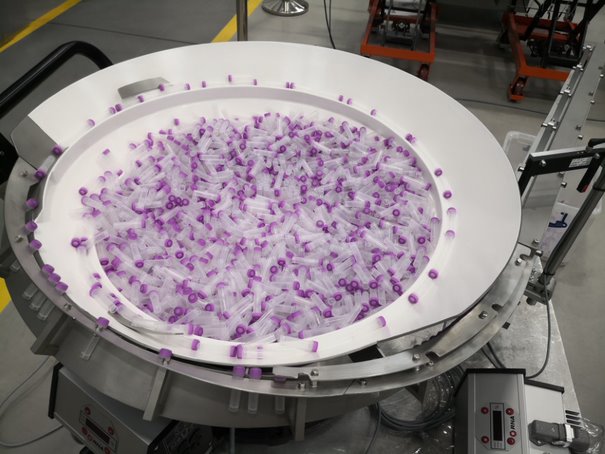

In the realm of automated assembly and manufacturing, efficient part handling is paramount. One indispensable tool in this arena is the Vibratory bowl feeders, a versatile device designed to orient and feed parts from bulk reliably. Coupled with a well-crafted tooling design, a vibratory bowl feeder can significantly enhance production efficiency and accuracy. This article delves into the crucial aspect of the vibratory bowl feeder tooling design.

The Crucial Role of Tooling

Tooling refers to the customised elements added to the vibratory bowl feeder to aid in part orientation, selection, and sorting. Well-designed tooling is essential to optimise the feeder’s performance for a particular set of parts.

RNA speaks on bowl feeders:-

Customisation for Optimal Performance

Tooling design is not one-size-fits-all. It demands a deep understanding of the parts’ characteristics and the specific requirements of the assembly process. Engineers often iterate through prototyping and testing phases to fine-tune the tooling for optimal performance.

Several factors need to be considered when developing the tooling:

- Part Geometry – The tooling surfaces must match the geometry of the parts to control and guide their motion. Complex or unusual part shapes may require more specialised tooling. 3D profiling of parts helps customise the geometry.

- Selection Method – The selection method to be used can vary and tooling is shaped accordingly. Many components are selected using entirely mechanical tooling and precise air jets whereas others are pre-orientated by tooling with final orientation obtained using sensors or vision sensors.

- Feed Rates – The feed rate required can influence the tooling selection with high rates often requiring multiple selection passes and merging of orientated parts. Attention must also be paid to the clearance of selection tooling to prevent part jamming in faster running bowls.

- Simplicity of Design – Overly complex tooling with many custom parts can increase manufacturing costs. Simpler modular tooling is easier to maintain and reconfigure.

- Materials – Bowls can be installed in a wide range of environments and suitable materials used must be accordingly. Pharmaceutical applications will require high grade stainless steels and closer attention to the level of finish when compared to an industrial application.

- Noise/Impact Reduction – Excess noise may indicate parts are impacting surfaces too hard. Durable linings such as polyurethane can be added to dampen the impacts and noise.

- Coatings – Specialised coatings like titanium nitride improve wear resistance and prevent galling for longer service life of the tooling in heavy duty applications.

By considering these factors and experimenting with different tooling configurations, manufacturers can achieve optimal performance from their vibratory bowl feeding systems. The tooling design itself is an art that requires experience and testing to master. But with the right tooling, vibratory bowls become highly flexible and efficient parts feeding solutions.

If you’re interested in streamlining your production lines with a new vibratory bowl feeder but unsure of where to start, give us a call on 0121 749 2566 to discuss your requirements. RNA also offer re-tooling and bowl feeder tooling modifications for our bowl feeders and conveyors. Please contact us with any enquiries or for further details.