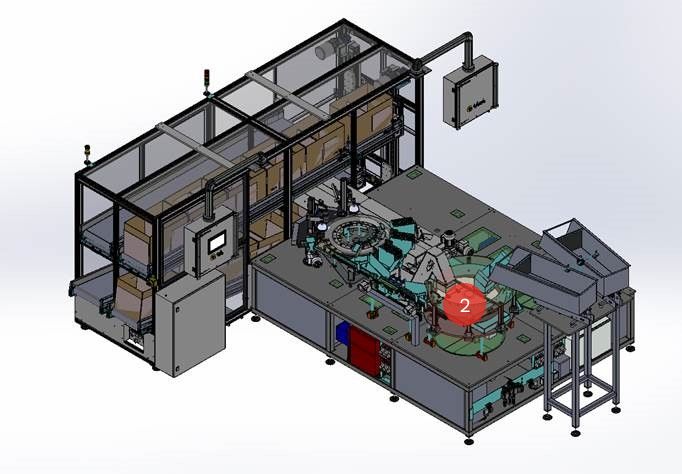

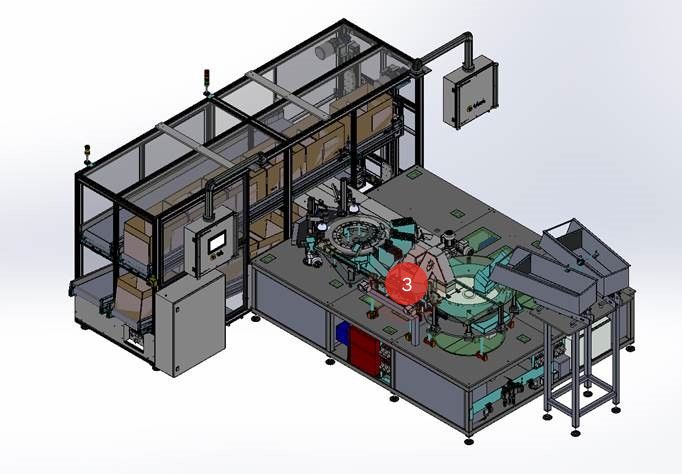

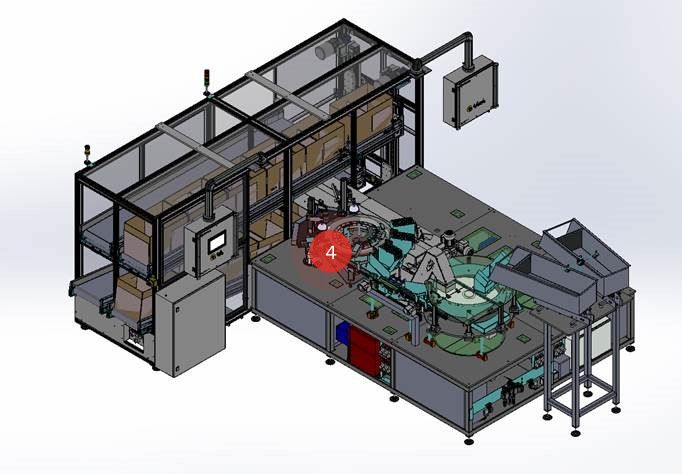

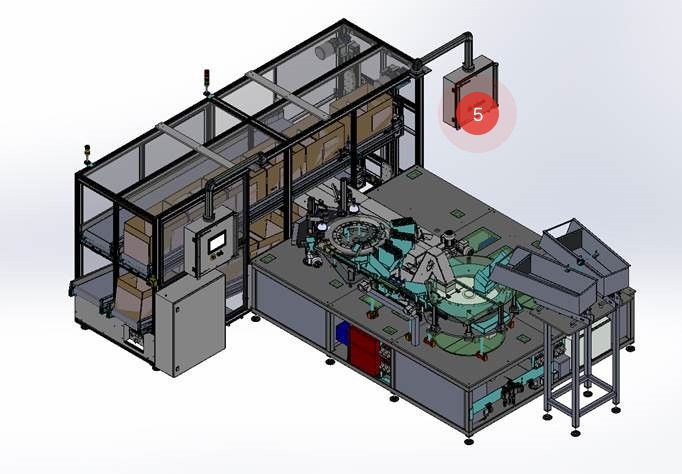

MK360™ Glass Disc Vision Inspection

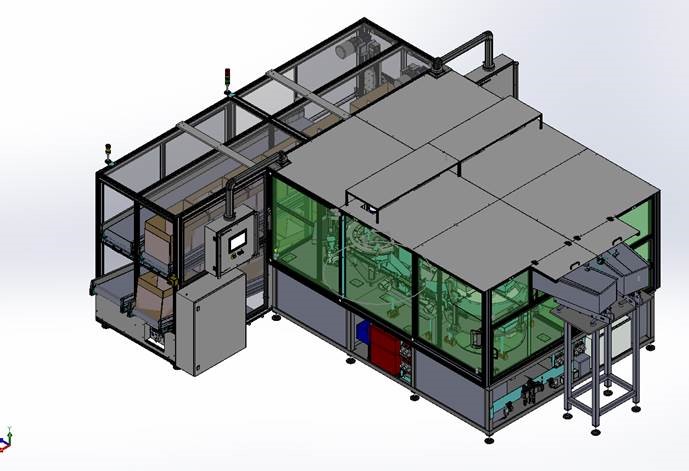

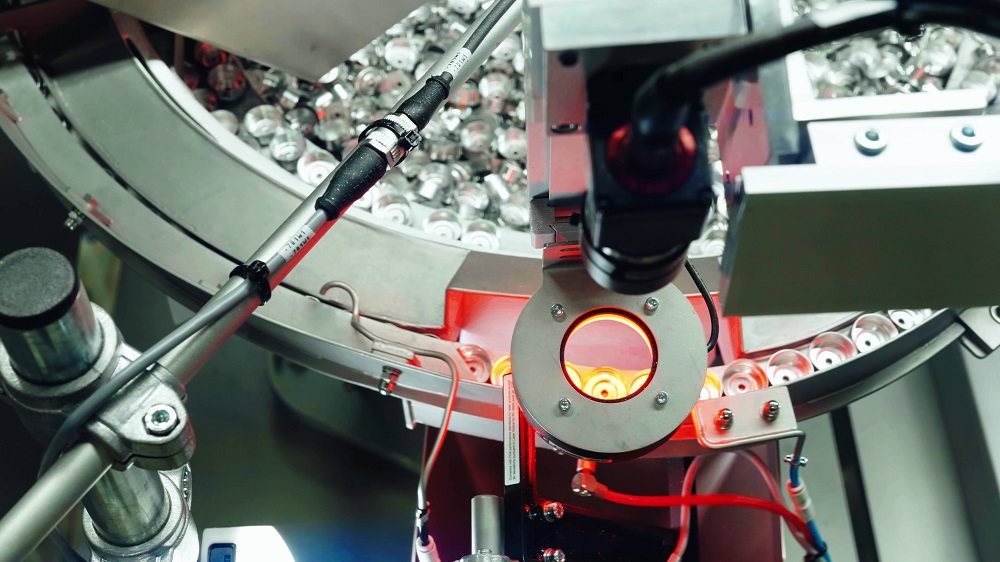

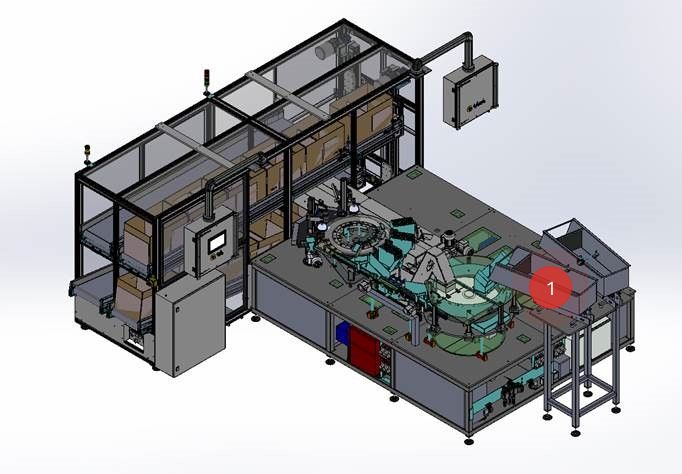

Reliable, accurate high speed solutions | The automated inspection machine RNA MK360™ is developed specifically for 360° quality inspection. A unique and novel approach to inspecting through the use of a rotating glass disc.

Downloads

Features

- Top, bottom and side inspection- Quality inspection applications

- Sorting applications

- OCR

RNA MK360™ provides high performance, high reliability, high speed, highly accurate vision inspection. The automated inspection systems are individually tailored to our customer’s specific requirements and their range of component parts which are to be inspected, with appropriate components of the system.

- 360° inspection (Top, bottom and side) for all types of defects

- Quality inspection applications

- Sorting applications

- Optical character recognition and verification (OCR/OCV)

The systems have been developed to meet high speed quality control requirements for 100% inspection.

Included in MK360™

Ultra fast

High feed rates at over 2000 parts per minute360° quality inspection

100% inspection and sorting through the use of a rotating discGentle handling

Smooth and gentle handling for minimal damage to the productRapid changeover

Minimum changeover between components that are different in size and shapeCost effective

Cost-saving benefits through reduced labour cost and high throughputWhat is the vision system for quality control?

A vision system for quality control refers to the use of machine vision technology to inspect, analyse, and ensure the quality of products during manufacturing or processing.

Applications of vision system include:

- Part verification (orientation, function, dimension, finished part features)

- Defect detection

- Automated vision test and measurement

- Colour verification

- Pattern matching

- Barcode reading and traceability

- Vision guided robot/robot guidance

Why Choose Us?

RNA has a team of qualified engineers to take your components from bulk, orientate, convey, inspect and place into your special purpose machine.

From initial enquiry RNA can offer a concept and design solution utilising its standard products as the core of a system with the aid of partners in the automation industry.

Bowl feeders and centrifugal systems have been used in many applications to feed components to a vision inspection system or specialised camera stations. From a simple intelligent sensor system to a full colour pixel camera recognition system RNA can offer a custom package to suit your quality control requirements.

- In house integration of a wide range of camera technology to provide the right solution every time.

- Full technical support with remote diagnosis capability.

- Front end feasibility studies for complete peace of mind.

Applications

- Suitable for inspecting a full range of components of different shapes and sizes

- Various hopper size

- Various bowl/centrifugal feeder size

- High performance vision system

- Up to 6 cameras can be integrated in one system

- RNA Bulk Hopper (depending on application)

- Bowl Feeder/Centrifugal Feeder

- In-Feed & Return Conveyors

- Inspection Disc and Vision System

- Integrated control system with HMI (Siemens)

- Interlocked guarding

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.