Feeding and handling in the battle against Covid-19

The battle against Covid-19 has delivered not just a vaccine at record speed but also a huge demand for supplement-vaccine products like syringes, needles and glass vials. RNA serve the pharmaceuticals and medical device industries by providing automated feeding and handling systems to meet increased demand related to Covid-19 vaccine production.

Given the nature of the pandemic, the supplement-vaccine products must be produced very quickly, and most importantly, be manufactured without any outside contamination to be safe and effective.

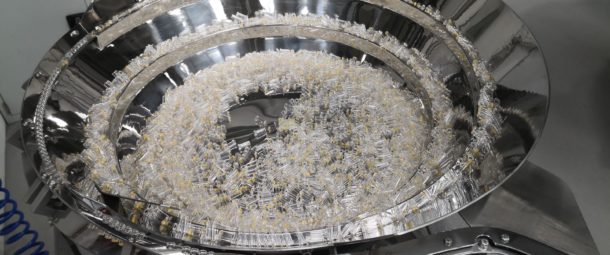

Bowl feeder systems are common but important feeding equipment when it comes to filling and packaging systems in the Covid-19 vaccine production, for example, syringes, needles and glass vials. Not only must bowl feeders be built to precise and clean specifications, they also need to meet the guidelines of the Food and Drug Administration (FDA).

Pharmaceutical feeder applications are among the most heavily regulated. High-grade 316L Stainless steel is used for all parts of the bowl with continuous seam welded and electro polish finish suitable for handling pharmaceutical products including syringes, needles and glass vials. This ensures the bowl surface is smooth, pit free and resistant to dust collection.

316L stainless steel with a medical grade electropolishing finish, that smooths the stainless-steel surface and removes miniscule metal burrs where bacteria can attach.

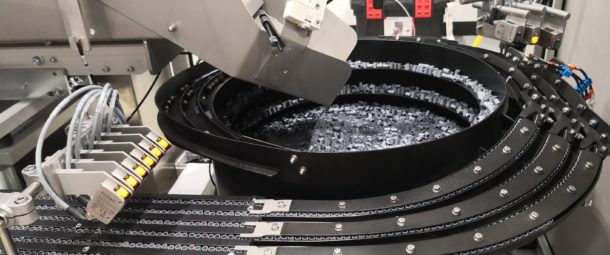

A multi-lane system design can provide a consistent feed at a higher output rate to accommodate high demand.

A quick release feeder can provide a low cost option for machinery needing rapid changeover between products, or where regular cleaning is necessary. Tool-less changeover can be achieve in literally seconds, which reduces downtime to almost zero. And because the changeover involves only one drive system, the need to invest in multiple bowl feeder drive units can be avoided. The quick release feeder can be integrated with other packaging and processing machinery for a wide variety of applications, including bottle feeding, tablet inspection, pick and place assembly processes or small batch runs applications.

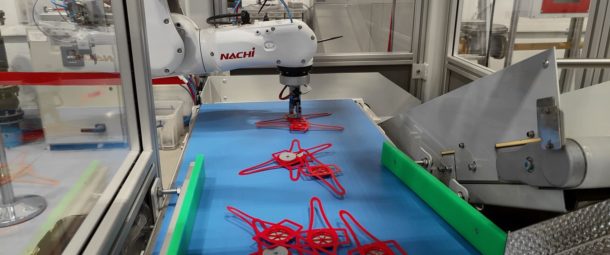

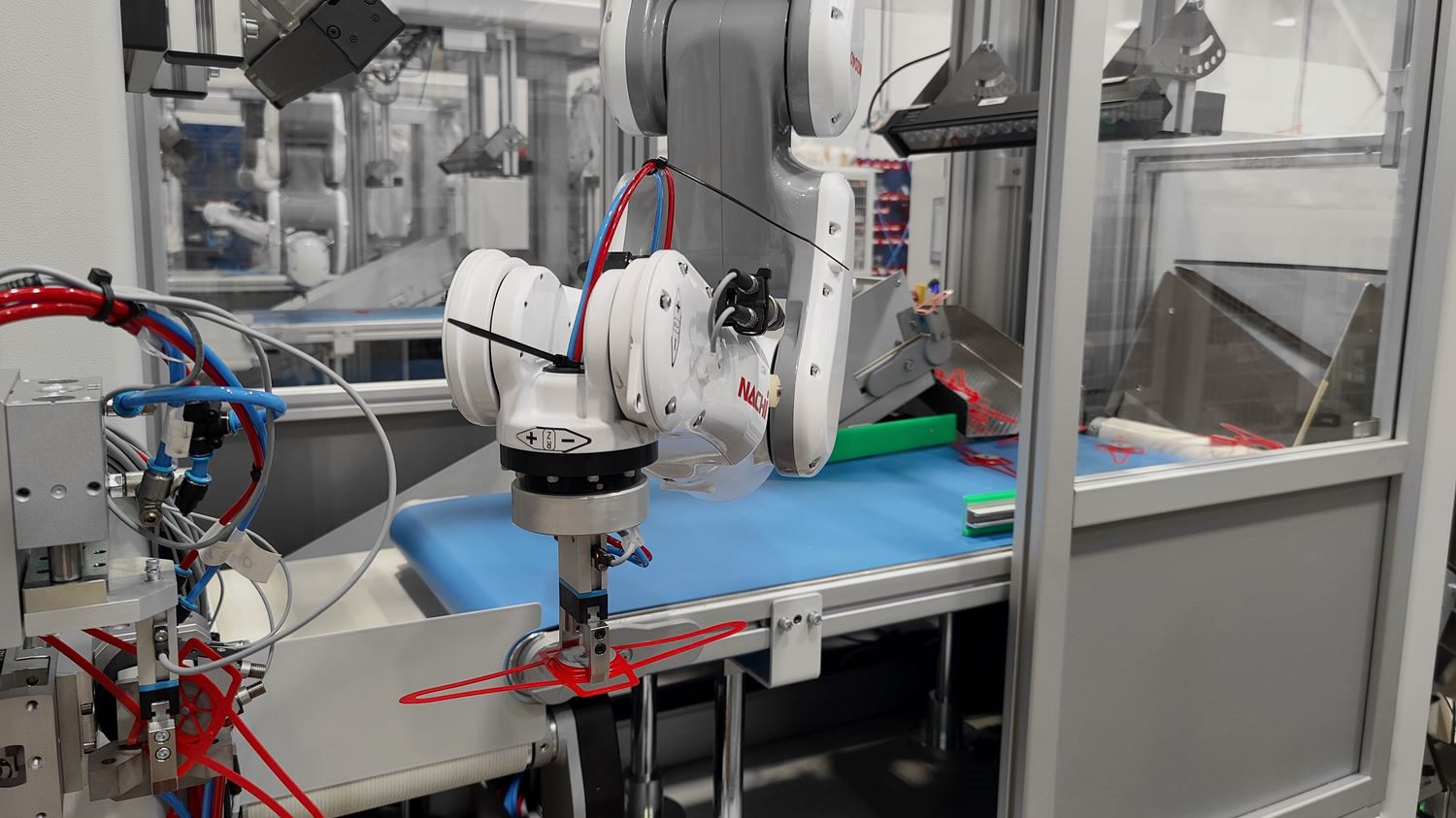

When feeding of dimensional and quantity variations is required, a flexible feed system comprised of pharmaceutical bowl feeder, vision and robotics can offer higher performance and efficiency. Flexible feed system can be easily reconfigured to accommodate production changes and is particularly suited for handling and feeding medical products of complex geometries such as syringe plungers.

The use of vision and robotics ensures the quality, reliability and speed of the manufacture, assembly and packaging, helping diagnostics manufacturers accelerate and enhance the production process of the COVID-19 supplement-vaccine products.

COVID-19 testing, as an essential partner to vaccines, remains critical to help countries around the world in the fight against COVID-19. However, testing is also one of the biggest challenges facing test kits suppliers amidst the outbreak. To meet the overwhelming global demand, diagnostics manufacturers have committed to increase production capacity of the COVID-19 test kits.

Applications

Contact

Send your message to a member of our team

Read our Privacy Policy to learn how we manage and protect your submitted information.