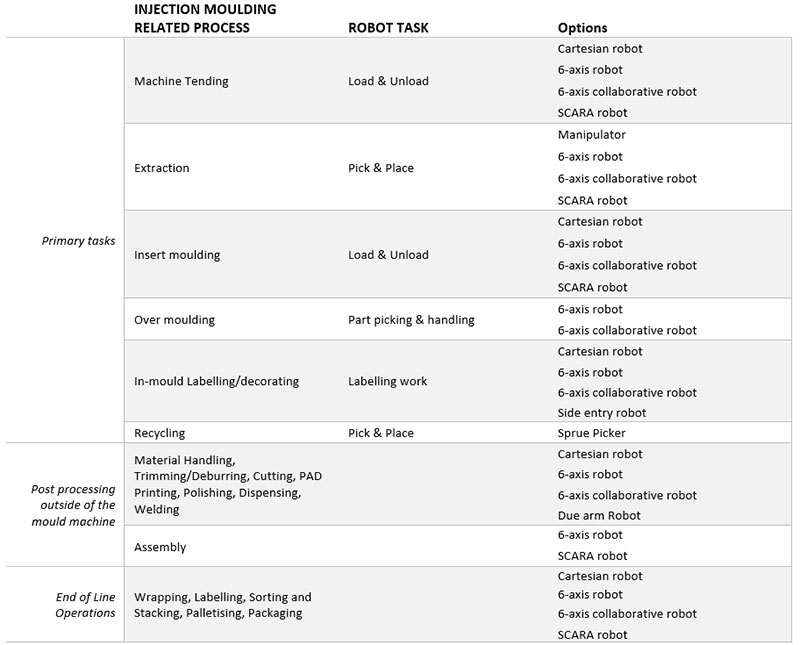

In today’s plastics industry industrial robots have been used across all areas of plastic production, including injection moulding related processes. From loading components into the injection moulding machine to finishing and assembling injection moulded parts, the use of robotics provides plastics manufacturers with a competitive advantage with marked increases in productivity and high quality.

Besides this, robots are more frequently used in post processing outside of the moulding process, such as welding, assembly and packaging tasks, driven by an increasing demand for more flexible solutions.

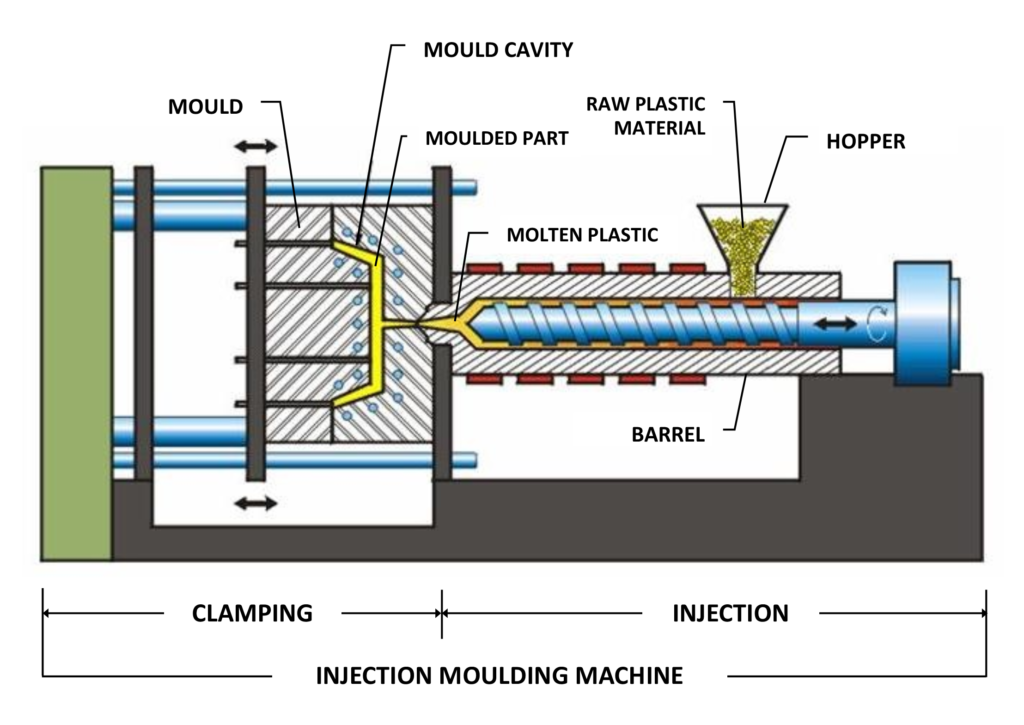

Plastic Injection Moulding Process

Plastic injection moulding is a commonly used manufacturing process for producing plastic parts. The injection moulding process requires the use of an injection moulding machine, raw plastic material, and a mould. Raw plastic material is fed into a heated barrel, melted, mixed and then injected into a mould cavity, where it cools and hardens into the shape of the mould.

The process cycle for plastic injection moulding is typically between 2 seconds and 2 minutes, and consists of four major stages: Clamping, Injection, Cooling and Ejection.

How Robotics work in Injection Moulding

Plastic injection moulding is a manufacturing process for producing plastic products in large volume. It is typically used in mass-production processes where the identical products are being made repeatedly and Industrial robots can perform these highly repetitive tasks. The most common application is machine tending – to unload finished parts from the injection moulding machine ready for downstream processes. In traditional injection moulding, this task is labour intensive and requires high consistency in handling due to the heat sensitive material being moulded. The use of a robot can relieve operators from repetitive work and the risk of injuries, resulting in improved product consistency and production capacity. Robots equipped with pneumatic grippers or vacuum can ensure the careful handling of newly injected moulded parts and avoid damage.

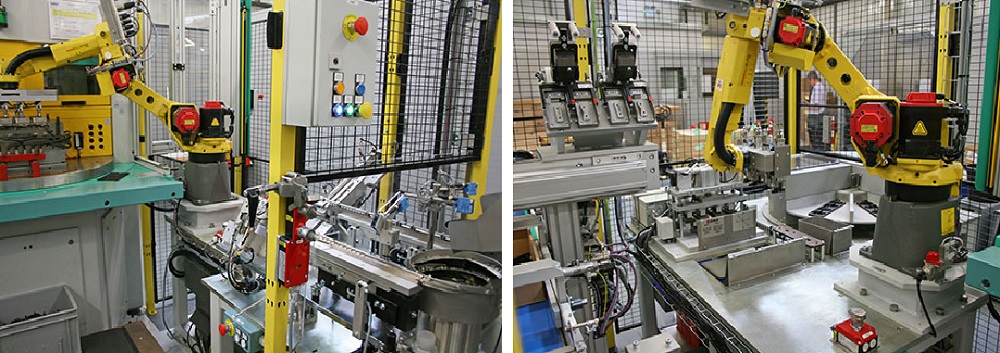

Robots are also relied on to perform insert moulding. Insert moulding involves encapsulating an ‘insert’ in moulded plastic. Most often, the insert is a metal object such as a pin, blade, threaded rod and so on. (Picture 1) Inserts can either be put inside plastic moulded parts during or after the injection moulding process. The following picture (Picture 2) shows two six-axis robots loading and unloading a vertical injection moulding machine and adding an insert to the moulding. The inserts are presented to the first robot, which loads them into the machine for the moulding process.

Picture 1 – Insert moulding (Source)

Picture 2 – Six-axis robots load and unload a vertical injection moulding machine and an insert to the moulding

In overmoulding applications where two or more separately moulded parts are combined to produce one part, for example, a toothbrush with rubberized grips on the handle, the process can be automated to varying degrees for fast and precise placement of parts. A robot can lift a moulded part out of one injection moulding machine and place it into another for the over-moulding process. This reduces labour and assembly costs, and improves the quality, reliability and integrity of the end product.

In-mould labelling/decorating is a process for labelling or decorating plastic injection moulded parts during the injection moulding cycle, which is another common area for robotic automation. An automated in-mould labelling/decorating uses robots to load pre-printed labels or decorated film directly into the open plastic injection mould. Labels or decorations are then permanently encapsulated within the injection moulded parts and become an integral part of the final product. A robot with custom designed end of arm tool allows precise positioning of label on the product with high stability.

As environmental concerns increase, recycling also plays a big part in the plastic injection moulding process. Materials such as thermoplastic can be recycled and used again. When the mould is opened, the entire molten plastic will cool leaving solid plastic in the sprue, runners, gates, cavity parts themselves (Picture 3). Sprue picker robots are pick-and-place robotic devices used for fast removal of the sprue or runner from the plastic injection moulding machine and place them into the granulator for recycling. The robot allows for pre-staging above the mould, which minimises action time in and out of the mould.

Robotics in Post Processing

Robotic technology plays a significant role for plastic injection moulding post processing. A robotic trimming cell provides superior repeatability when compared with a human performing the same task, and it increases flexibility by performing multiple operations. A robot will consistently dispense the same amount of sealant or adhesives following a highly repeatable pattern, offering greater shot accuracy, improving cycle times and reducing waste.

With or without vision, robots can pick and place plastic moulded parts for further operations such as inspection, testing and hot stamping.

In the assembly of injection moulded parts, robots can perform complex welding operations using laser, ultrasonic and infrared, increasing precision and driving down cycle times.

Robots also meet the needs of automated finishing, ranging from PAD printing to polishing.

Further, automating the end of plastic production line can make a big difference to production rates and cost effectiveness. Robots can liberate workers from strenuous and repetitive manual work such as wrapping, labelling, palletising, and provide flexibility for quality packing, storage and logistics.

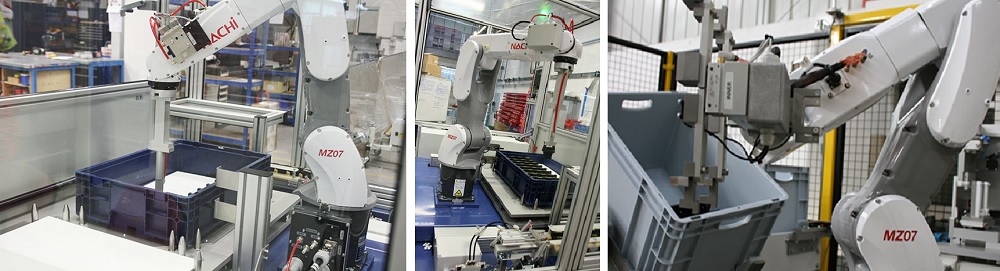

Picture 4 – Robot packs plastic filler caps

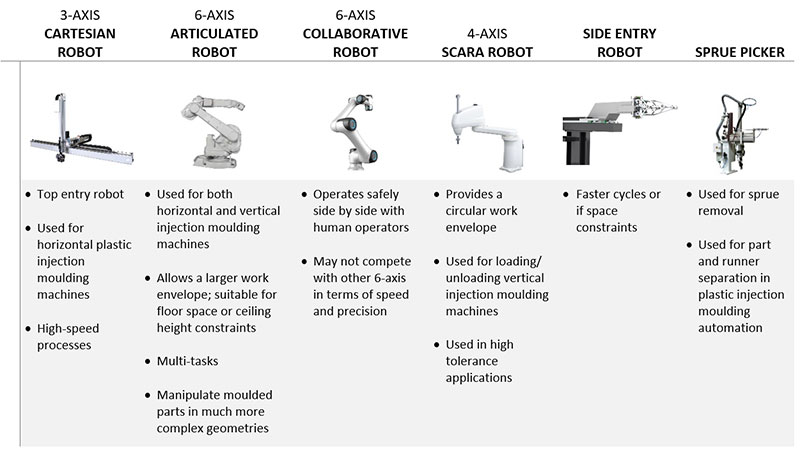

Plastic Injection Moulding Robots

With fast ROI, Robotic automation is no longer the exclusive domain of multinational giants. Small enterprises can also cash in on robots. Talk to a systems integrator to determine the best solution for your plastic production line.

Reference

- “What’s New with Robotics in Injection Moulding?” Bennett Brumson, Robotic Industries Association, 06 January, 2010. Link

- “Robots”, Retrieved from Link

- “In-Mold Decorating / In-Mold Labeling Automation”, Retrieved from Link

- “What benefits could robots offer injection moulding manufacturers?” Nigel Flowers, RSS Print, 13 August 2019. Link

- “Robotic Moulding Process”, Retrieved from Link

- “The Robotic Future in Injection Moulding”, Retrieved from Link

- “Plastics Processes”, British Plastics Federation, Retrieved from Link

- “Injection Molding”, Retrieved from Link